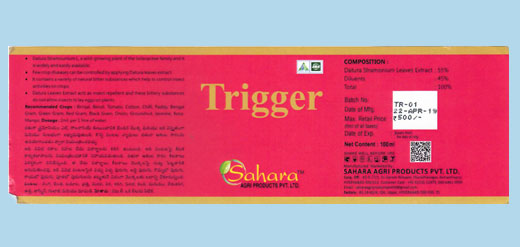

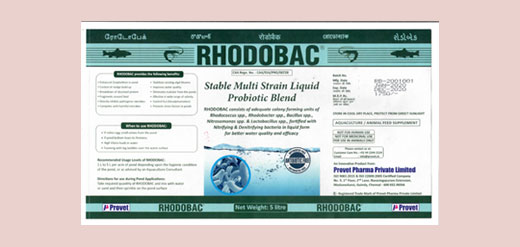

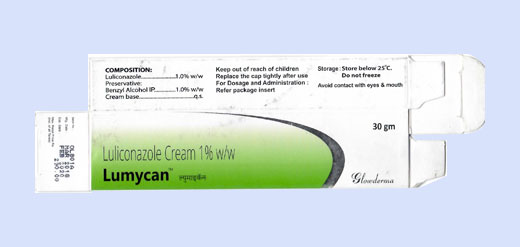

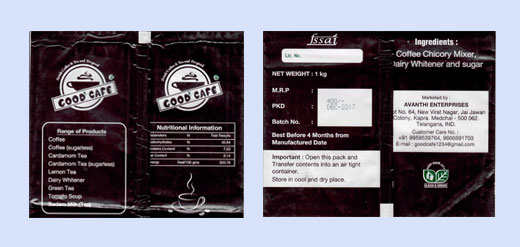

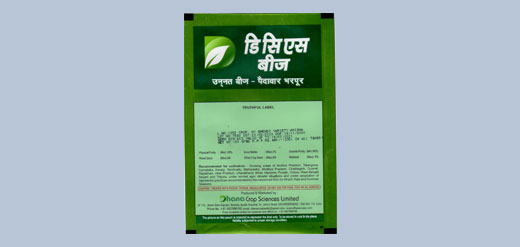

Packaging is vital subject of product selling in current dynamic world. Batch number/Batch code or the lot number should be judicially on the product as specified by the country regulations. The batch coding is important as it may be required especially in case when a product is recalled, or there is a failure with regards to the quality of that batch of products. It helps in tracing and tracking of the product from manufacturer to end user.

Batch coding is must for product quality and better upgradability of customer satisfaction. Different industries require batch coding machines capable of applying codes and data to a wide variety of products and packaging. Selection of suitable printer / printing technology plays big role in coding cost and maintenance.

Continuous Ink Jet Printer (CIJ) / printing technology follows NON CONTACT PRODUCT CODING METHOD. As Indian manufacturer of inkjet printer (BIS certified), our Numeric printers meet all most all kinds of applications. Optimum coding cost with lesser maintenance and best possible post-sales support locally is proving us a better coding Indian printer supplier in the coding industry.

Our inkjet printer installation provides required batch coding on your product and peace of mind to you with its reliability. NO locks / NO RFIDs on our consumables, NO Pre-set counter on PUMP MECHANISM, NO locking period to service maintenance are levied to hold the valuable customer in the name of consistent quality coding procedures.

just give us a call

S100 - One inkjet printer for all most all coding applications

Thermal Inkjet (TIJ) printers use standard ink cartridge systems and do not require any bottles of inks or solvent, making thermal inkjet printers clean and simple to use. Thermal inkjet printers use a drop ejection process, storing ink in a cartridge that regulates the pressure of the fluid. TIJ prints in high resolution up to 600 x 600 dpi, like a desktop ink jet printer. CIJ prints a low-resolution dot pattern. Print Speed high when compared to CIJ.

TIJ Has Lower Total Cost of Ownership

- Simple but versatility TIJ inkjet printer.

- High print speed, reliable and maintenance-free.

- Robust and economic, easy in operation

- TIJ systems as a realistic and cost-effective alternative for both porous and non-porous substrates.

- Today, thermal systems are much more competitive when comparing speed.

- CIJ OEMs may offer printing systems at bargain prices, knowing they can recover the equipment cost with ongoing maintenance and ink.

- Despite saving money upfront with discounted systems, the initial capital investment needed for CIJ systems still exceeds that of TIJ printing technology.

- It is truly zero-maintenance and drastically decreases cost of ownership.

Image Quality and Resolution

The resolution and faster-operating speed of CIJ printers sacrifices image quality. Some companies may rely on image or QR barcode coding for product tracking in the supply chain wherein image quality / resolution matters. Thermal inkjet systems create 300-600 dpi imaging, which is very much useful to ensure quality coding.

- The inherent superior image quality of TIJ offers more printing opportunities.

Now TIJ Works for More Substrates

At one time, TIJ printing was limited to porous substrates such as non-glossy paper and cardboard. Now inks Available for Porous substrates is Aqueous based Inks and Non-Porous Substrates is Solvent Based Inks solve the problem of printing on difficult substrates such as glossy paper, some metals, glass, flexible films, and ceramics.

TIJ makes printing changeovers faster and cleaner because the ink cartridge is also the printhead. As a result, changing colour or changing ink formulations to print on different substrates is as simple as swapping a cartridge. That saves valuable production time for industrial printers.

Printer Maintenance and Reliability

- Maintenance stops production and adds to the annual operating cost of the CIJ system.

- In comparison, the cartridge-based printheads in TIJ systems require much less service.

- A fresh TIJ cartridge can be quickly swapped to keep the printing line running, which allows more time for cleaning and servicing the removed cartridge.

- TIJ systems can start and stop almost instantly, offering the convenience of intermittent operation or easy changes.

- TIJ systems are more intuitive, with more straightforward user guides and less operator training required.

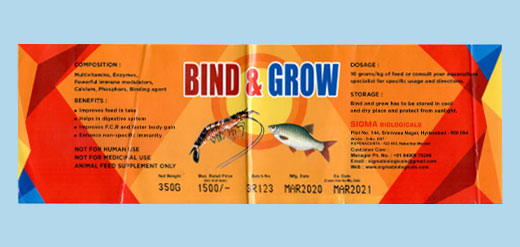

Applications

- Pharmaceutical Packaging

- Demands of food manufacturing production lines.

- Beverages Industry

- Cosmetics & Beauty Products